These are projects completed for various classes at Brigham Young University

Mechatronics

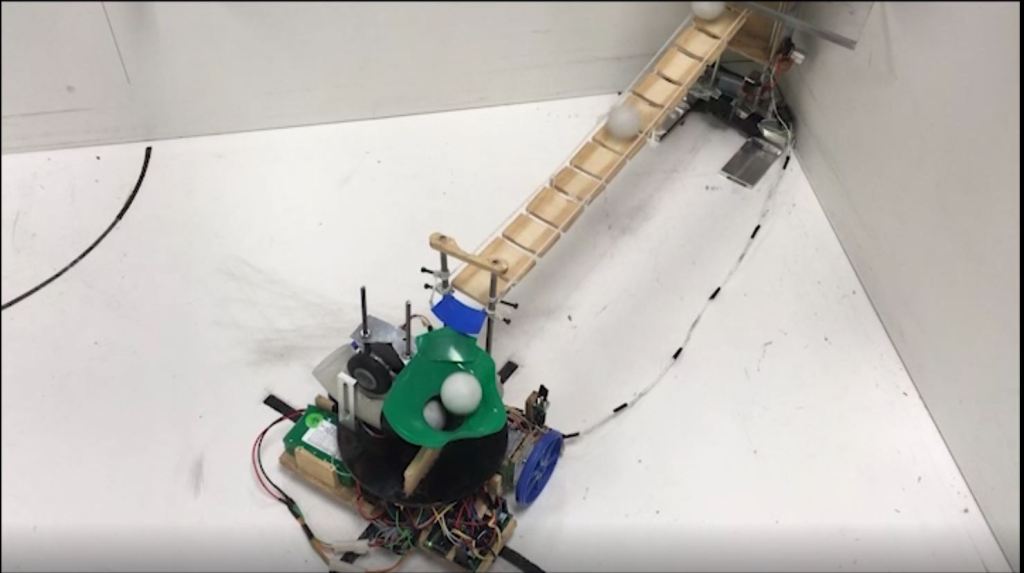

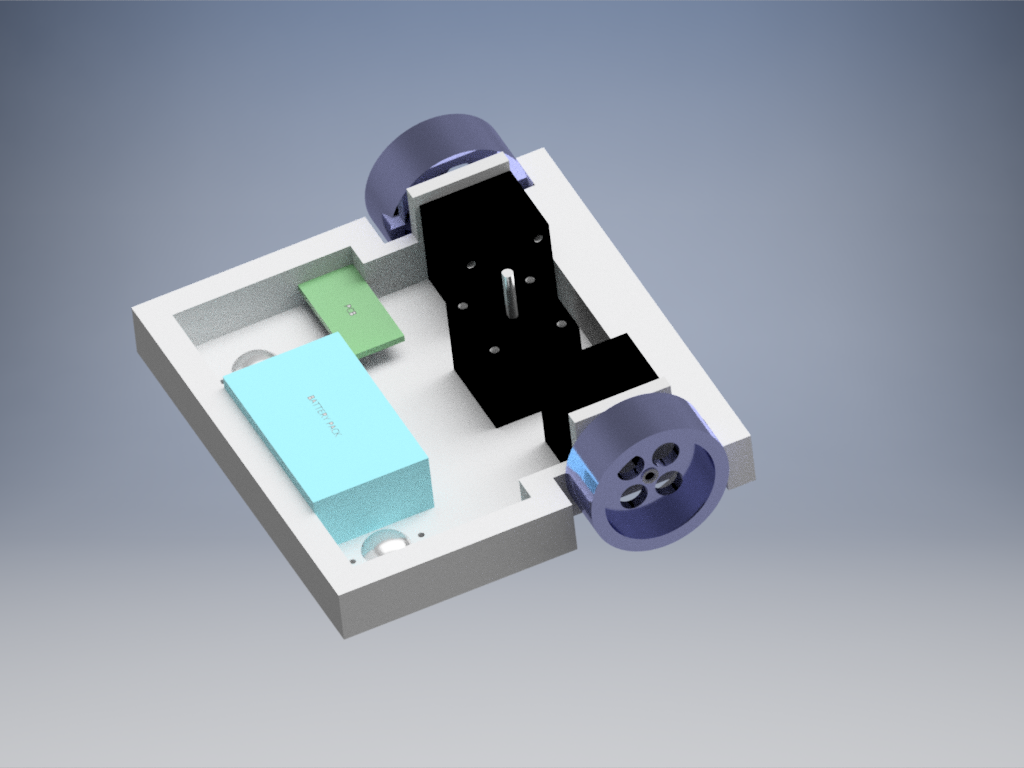

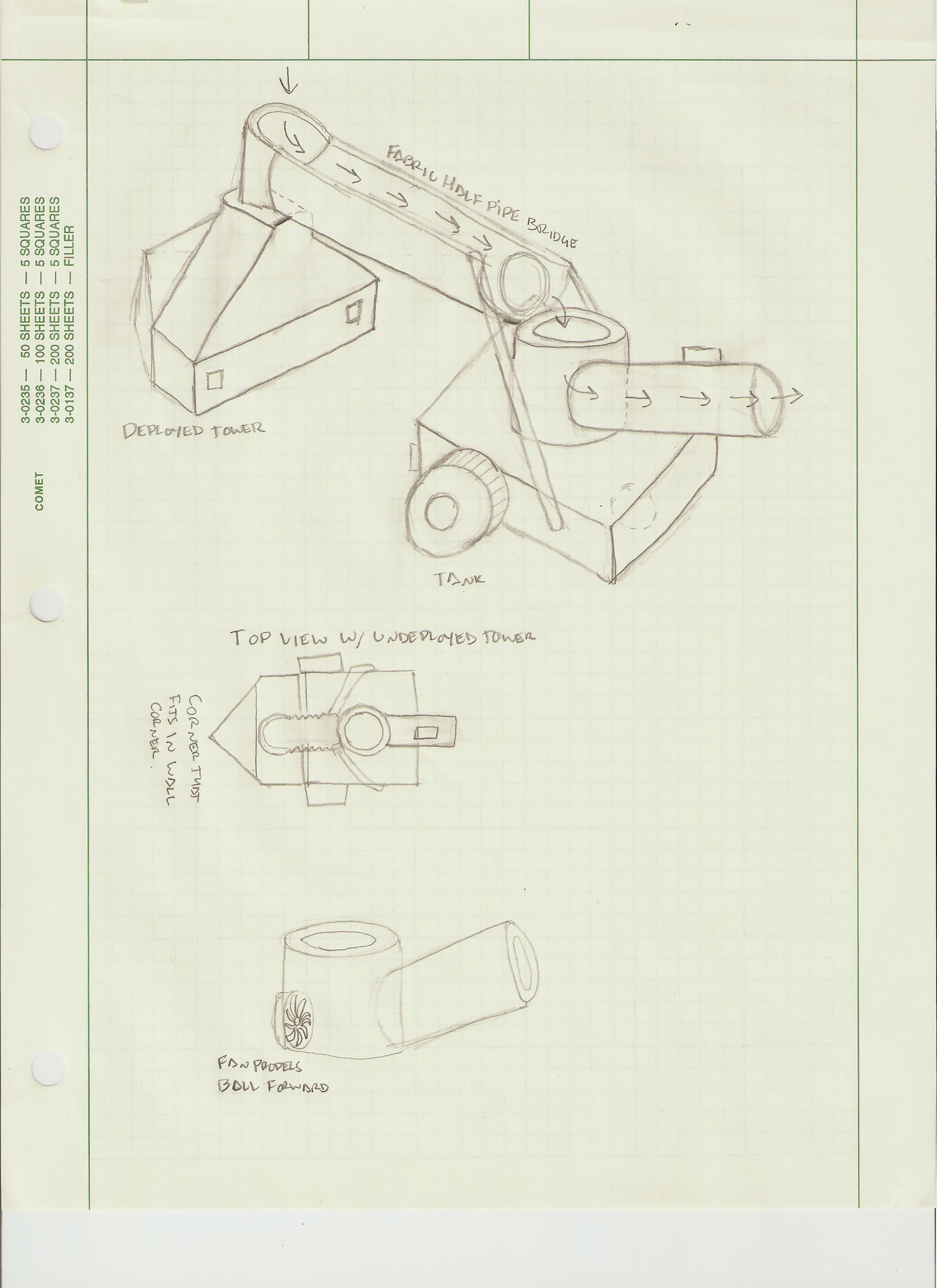

The objective was to create an autonomous robot that could be put in an enclosure, pick up ping pong balls and shoot them to one of three goals. The goals on each corner would emit an IR signal one at a time and only the goal with the current IR signal would score points.

Our robot, which we called Arturito, featured a PIC24 microcontroller which would control the stepper motor driver as well as interpret the signal from an IR sensor and switches. It also featured an aluminum tower which could detach from the main body of the robot. This tower was left in the corner where the ping pong balls would be picked up. The balls travelled via a wooden bridge to the turret. The turret had both a stepper motor and an IR sensor to detect and rotate to face the corresponding goal and shoot the loaded ping pong balls.

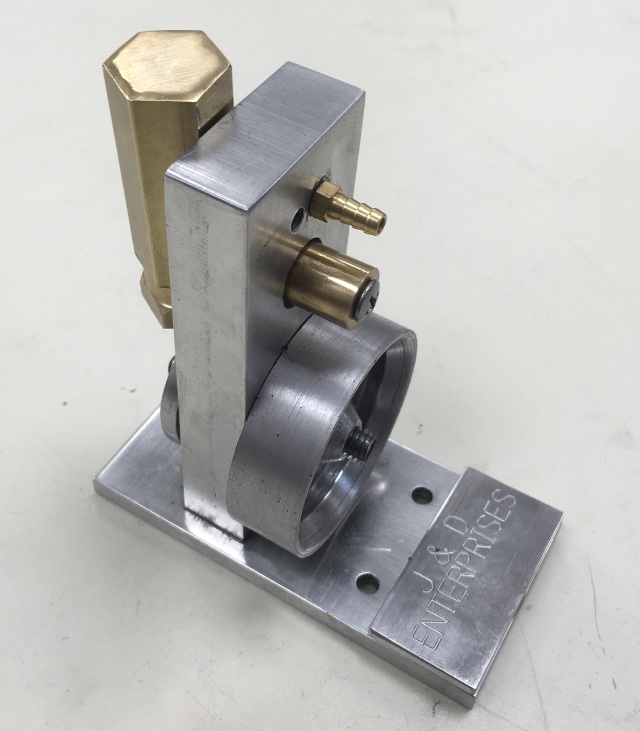

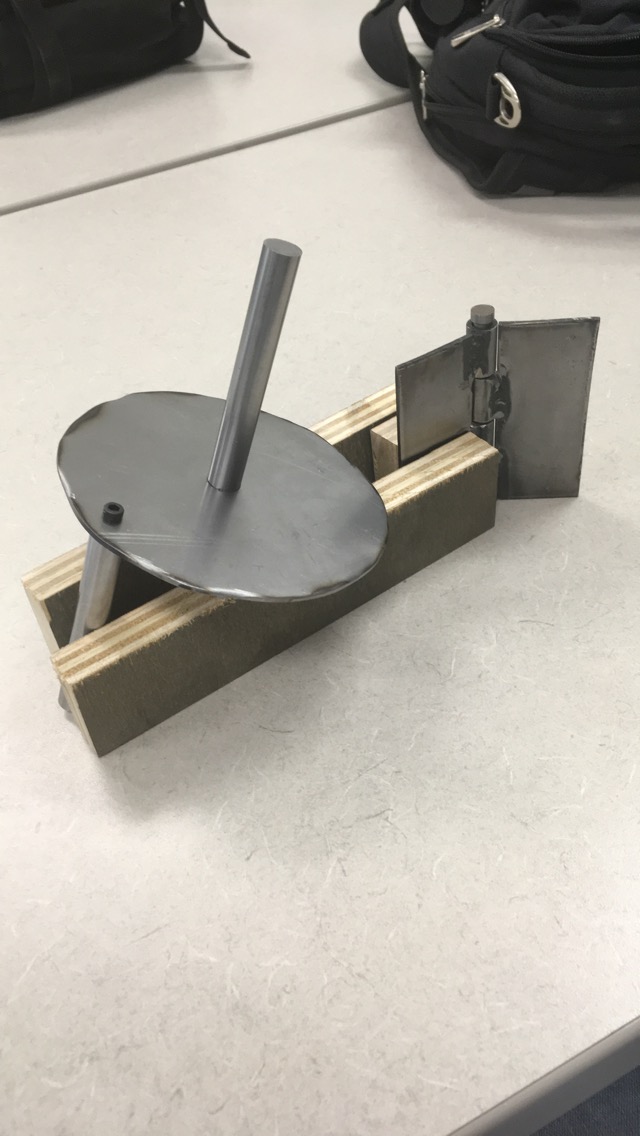

Manufacturing Processes – Pipsqueak Engine

The goal of this project was to become more familiar with various manufacturing processes. The original design was already provided, but we needed to evaluate each piece and make recommendations on how to improve either the design or the manufacturing process. This engine had a piston and cylinder with holes for intake an exhaust. By passing pressurized air on one hole, and allowing it to exit on the other, the piston and cylinder turned a crank wheel connected to a shaft and flywheel.

The towers were cut and milled. The crank wheel was made with powder metallurgy. The shaft, piston and cylinder were turned and drilled with a lathe and the flywheel was cast.

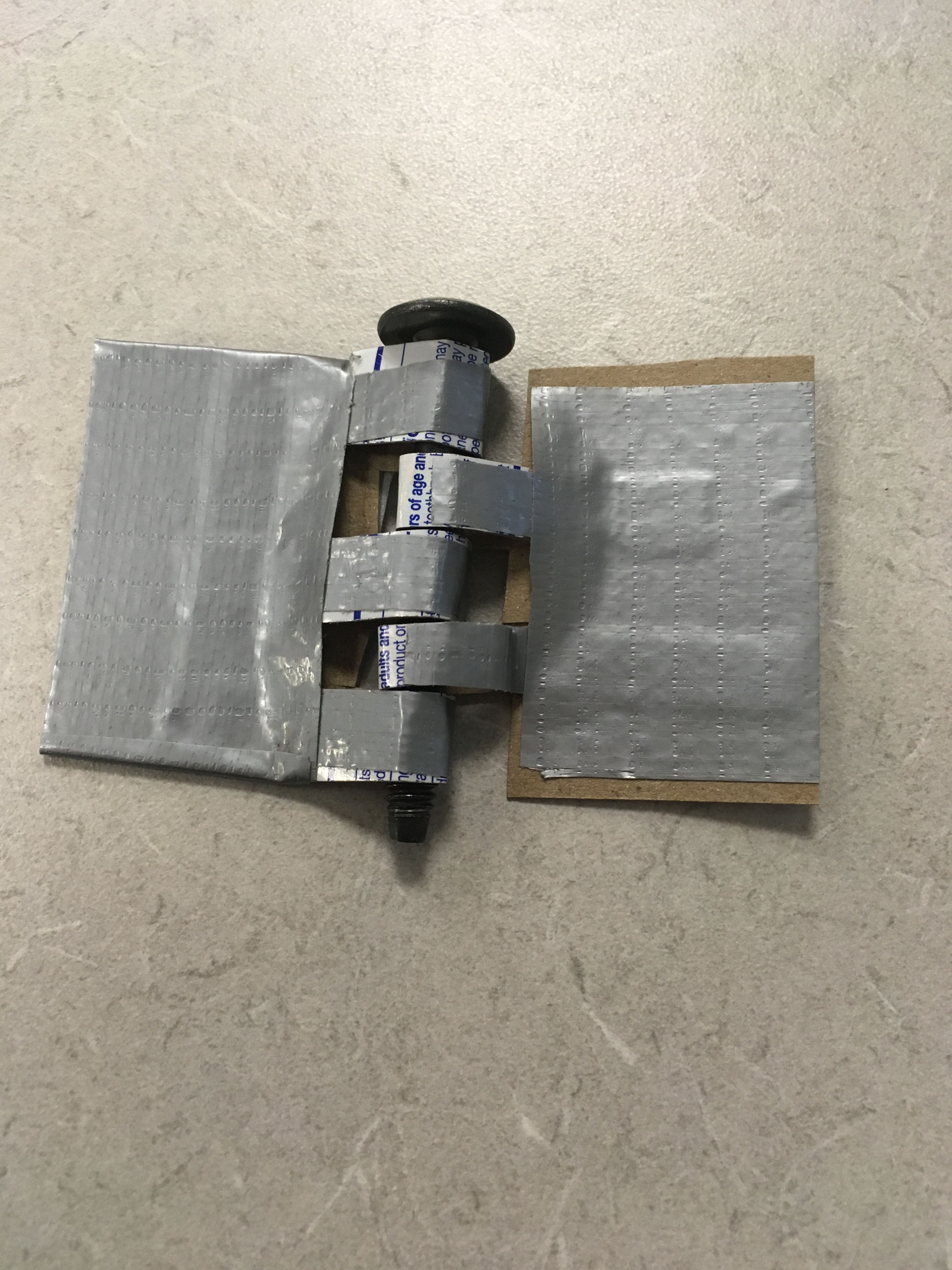

Intermediate Materials – Door Hinge

For this project, my team needed to choose an everyday item that we would manufacture. The purpose was to pick both the material and the manufacturing method. My team chose a door hinge. We used low carbon steel and constructed two hinges from a flat sheet and a rod which were welded together.

We also constructed a test device which we could mount on a Mill to test the wear on one of the hinges after 7500 cycles (which would be about 10 years of wear). Toward the end of the test there was an audible squeak.

The other hinge was placed on an Instron machine and pulled perpendicular to the pin to measure the stress it could endure before failure. We tried both attaching it to plywood and pulling the hinge directly. The wood failed at 514 lbs of force while the hinge failed at 4180 lbs of force when pulled directly.

Capstone – Product Development

My capstone project is under NDA so I am unable to share images or go into much detail but it is by far the project I learned the most in. The only thing I can share is the project goal which was to: Design, Build and test a prototype of a disposable miniature fluid dispensing system.

It ended up being a very simple design, but going through the steps of establishing Market Requirements, Key Performance indicators, Concept Development, Subsystem/System Engineering was an incredible experience. It really allowed us to be confident that our design was the best one for the application our sponsor needed and they were very happy with the results.

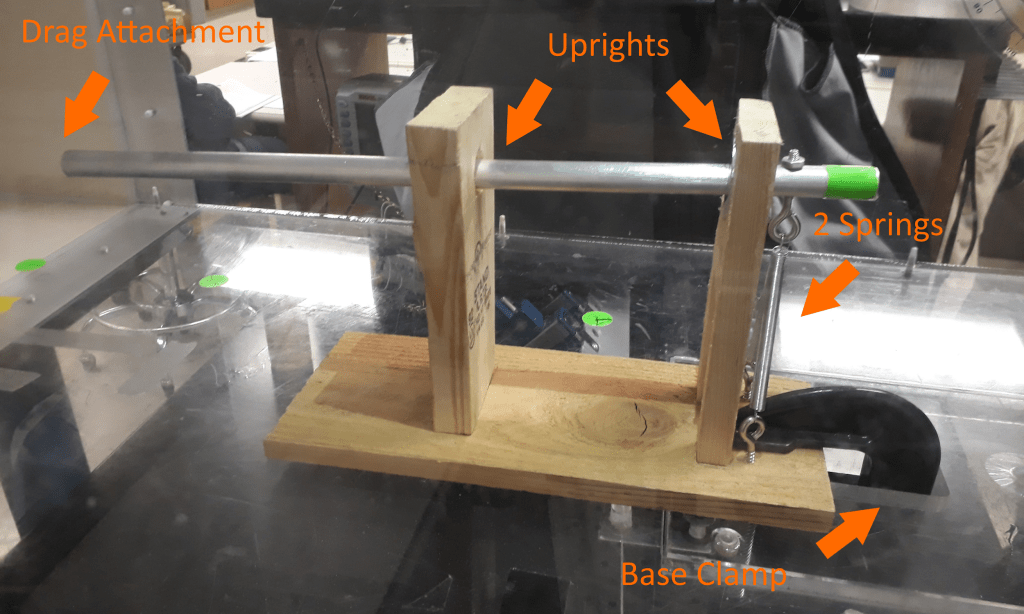

Measurements – Drag Force Measuring Device

The purpose of this project was to construct a device to measure drag force for different shapes inside a wind tunnel. The displacement in the springs was used to measure the amount of force that was exerted on the attachment (we measured a cup shape and a flat disk). We filmed the device at different wind speeds and then used a MATLAB script to break down the video into still frames. Another MATLAB script isolated the Neon green tape at the end of the rod on each of the frames and we used the displacement data to obtain the displacement of the springs. The device worked well to get drag force measurements for high wind speeds, but it struggled at low speeds due to the friction in the uprights.